Cadmium Applications

Cadmium in alloys

Cadmium Applications

Main cadmium alloys and their applications

Benefits in brief

- Higher hardness and wear resistance

- Better mechanical strength

- Improved fatigue strength

- Enhanced castability

- Very high ratio of conductivity over strength

- Lowering the melting point of soldering alloys

Copper-cadmium alloys

Copper-cadmium alloys containing 0.8-1.2% cadmium exhibit almost double the mechanical strength and wear resistance of pure copper, while retaining 90% of its conductivity. These alloys can also be severely cold-rolled and drawn without making them susceptible to softening during heat cycles or soldering. Key application areas of copper-cadmium alloys include auxiliary contact wires, flexible dropper wires and stranded catenary wires for railway overhead electrification, tinsel wires for high flexibility applications, special bunched cables for aviation, military and aerospace uses, and electrical components such as contact strips.

In some of these applications, not only the conductivity of the copper-cadmium alloy is important but also its tensile strength. Applications include free-hanging conductors in railway catenary systems and power lines. For other applications where frequent bending occurs, fatigue resistance is most important, for example in some medical appliances. Finally, it is possible to combine all these characteristics advantageously, as in small power and signalling wires in airplanes.

The production of copper-cadmium alloys for electrical applications is well controlled. Once the alloy is made, the cadmium remains inert for its complete lifetime, after which it can be easily recycled.

Lead-cadmium alloys

Soldering and brazing alloys

Cadmium is also added to metals to lower their melting point. These are used for defence & aerospace applications and for brazing fillers.

Intermediate temperature soldering alloys

Cadmium alloyed with silver, zinc and/or tin makes excellent solders with a tensile strength two to three times higher than most common solders in this temperature range. They are often used in applications where temperature sensitivity prohibits the use of silver solders with higher tensile strength. Zinc-cadmium alloys are used for soldering aluminium; zinc-cadmium-tin alloys are used for soldering magnesium.

Silver-brazing alloys

The inclusion of cadmium in silver-brazing fillers reduces the brazing temperature and shortens the duration of the brazing process. Applications include the brazing of turbine wheels in gas compressors, and of boiler feed pumps in power plants.

- vertical lift bridge

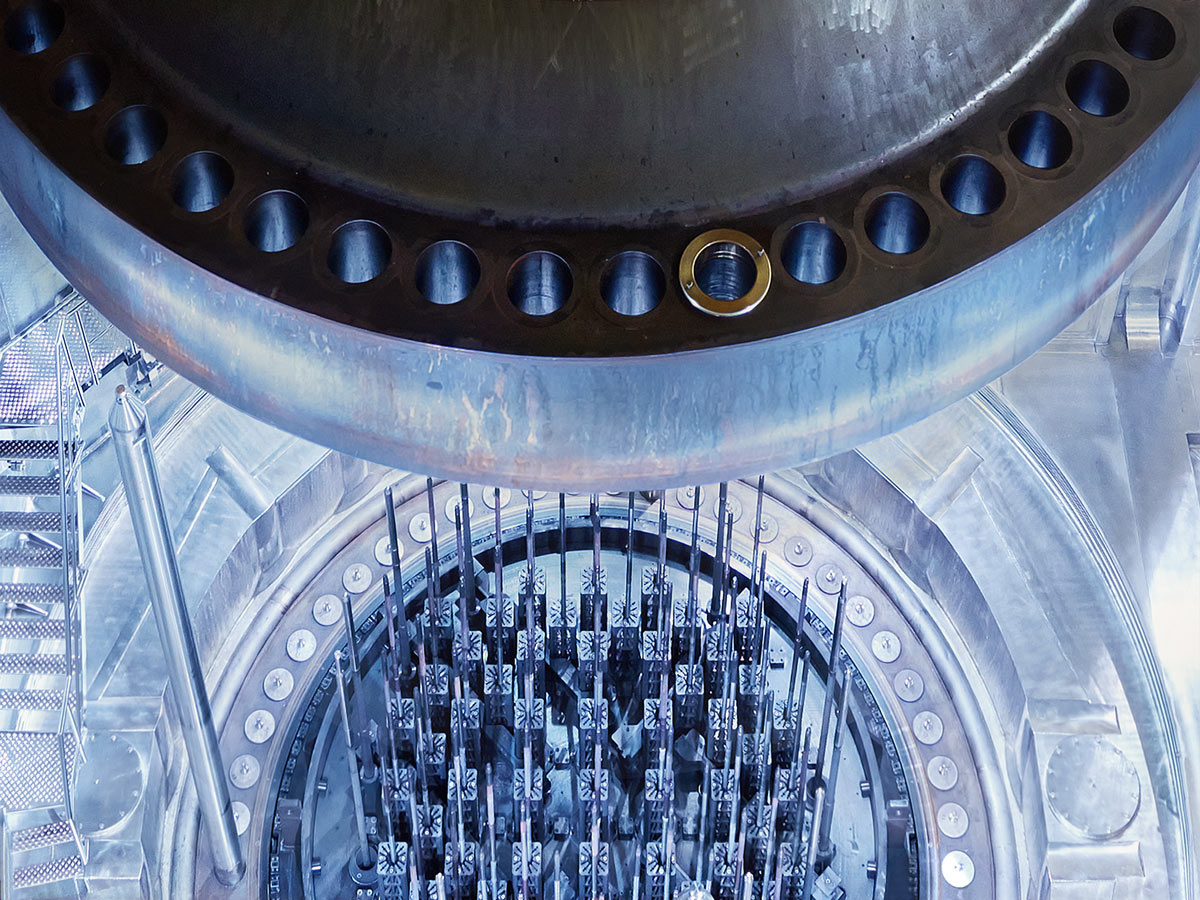

- control rods in a nuclear reactor

Silver-cadmium alloys

The addition of 10-15% cadmium or cadmium oxide to silver improves resistance to material transfer and electric erosion, and also gives some degree of arc-quenching. These alloys are used in many heavy-duty electrical applications such as relays, switches and thermostats.

Silver-cadmium-indium alloys

“Woods Metal”

The tin-lead-bismuth-cadmium alloy which melts at 70°C (more commonly known as “Woods Metal”) is used in the bonding of metallized ceramic and glass components to metal frames and chassis, where higher soldering temperatures are not possible. Applications include mounting glass lenses during grinding operations, and machining jet engine turbine blades and vanes.

Tin-cadmium alloys (white metal alloys)

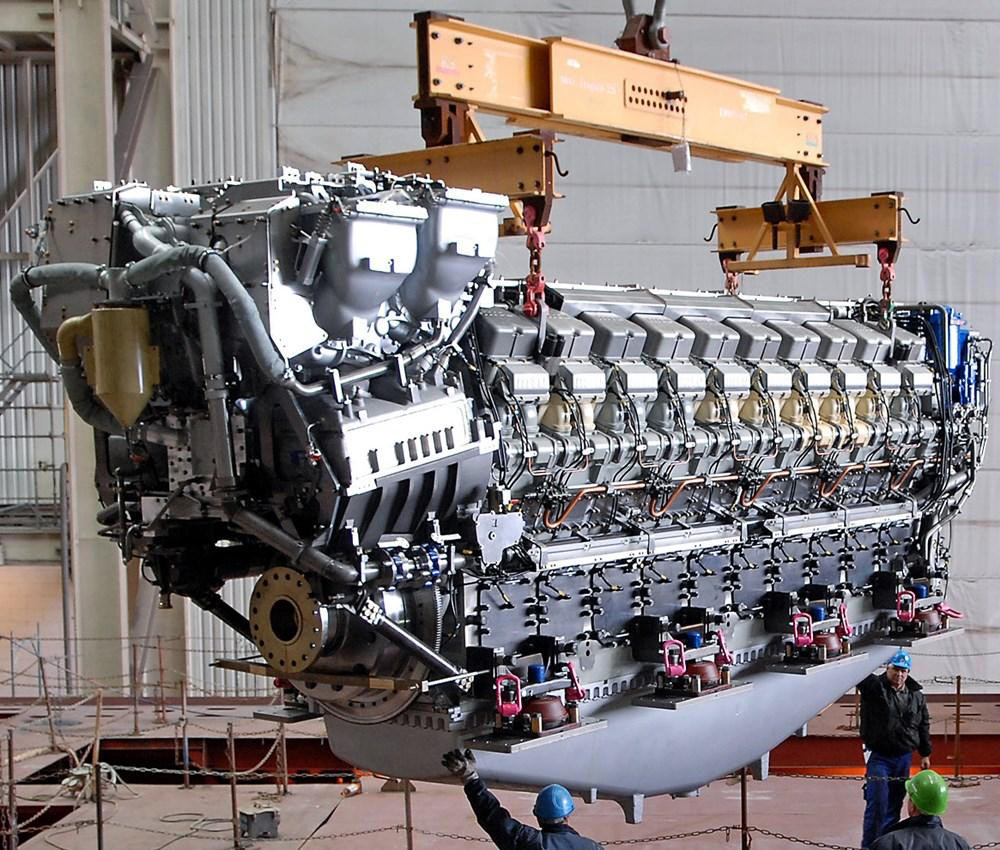

Tin-cadmium alloys containing up to 1.5% cadmium display improved tensile strength and fatigue strength. These alloys are used in the marine industry in ship engines, turbines and gearboxes. Specific applications include main bearings, crankpin bearings, crosshead bearings, guide shoes, camshaft bearings, and also thrust bearings because of their excellent load carrying capacity and low coefficient of friction.

Zinc-cadmium alloys

Zinc alloys containing 0.025-0.15% cadmium are used as sacrificial anodes in the corrosion protection of structural steelwork immersed in seawater. Addition of small amounts of cadmium increases the performance of the anodes in salt water.

Cadmium-zinc alloys

Zinc-cadmium alloys with up to 90% cadmium are used for decorative castings and fashion accessories. These alloys have a low melting temperature and are easy to cast. This use is not authorised in the EU but is very common in Asia.